I recently wrote about how Avtec can help keep unwanted odors at bay because our energy efficient EcoArch hoods and conveyor systems make cleaning much easier.

But that doesn’t stop with Avtec.

Our Randell refrigerated products are also engineered to be easier to clean and help prevent those less-than-pleasant odors. Just like doing routine maintenance on your car, the better you take care of your refrigerated equipment, the better it will take care of you – and your customers with a strong sense of smell.

This has never been more important to owners and operators dealing with staff shortages and employee turnover. And it starts with picking the right equipment.

Downsides of Forced Air Prep Tables

A majority of commercial prep tables are “forced air.”

Air in the refrigerated base is directed through the pan opening to keep the pans cool. Since air is coming from a single source, this design often incorporates ducting and fans to help distribute the air properly. And this ducting is a perfect place for pizza toppings and loose ingredients to fall into.

This can also create issues in holding temps because the cold air falls out of the base every time the door is opened. That means the air blowing over the toppings can fluctuate because it’s using the same air that’s in the base.

Don’t believe me? When you are home, take off your shoes and socks, and open your refrigerator or freezer … you’ll feel the cold fall on your feet!

Cold Wall Cooling to the Rescue

When conditions require improved temperature performance, Randell utilizes “cold wall” conductive cooling.

With cold wall cooling, the pan opening is completely sealed from the base and independently-controlled refrigerated copper-tubing-wrapped pan openings create a frost line around the pans. That keeps the toppings cold regardless of how many times the base is opened.

All our cold wall prep tables include a large cleanout port as standard:

At the end of the shift, associates can add warm soapy water to the pan opening to clean and disinfect the area and easily drain through the standard flexible hose with gate valve. The valve can drain into a bucket for removal if a floor drain isn’t located nearby:

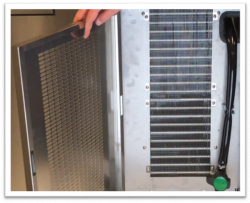

This hose and valve are strategically located behind the hinged louver at the compressor housing:

Don’t Forget to Clean the Compressor!

Too often compressors are out of sight and out of mind.

But this forces associates to look at the intake to the refrigeration system when draining the pan opening. Keeping this clean will help keep your equipment running better, cooling more efficiently, and extend the life cycle for operators.

And prevent those foul odors!

Having fractional pans to resupply the rail, or speed up making complex menu items, is a popular option for our customers. And with more options of pans – and faster pace of work – spillage can and will happen.

Thankfully, our drawer cartridge systems are also designed to be easily removable to promote cleaning:

Dave Rademacher, Randell’s Product Manager of Refrigeration, shows how to remove the drawer system in as little as 45 seconds to give easy access to clean the full refrigeration cavity.

Cleanability is critical for extending the lifespan of your equipment and improving its performance. And clean equipment makes sure the smells coming from your kitchen are pleasing to your customers – instead of odors that send them out the door.

Randell, Avtec, and the rest of the Electrolux Professional Group family will help you design easy-to-clean equipment, with the details and options needed in today’s fast-paced commercial kitchens.

Jefferson Kenney

Product Line Manager – Ventilation

Electrolux Professional Group – Avtec

800-621-8560 EXT 6492