From add-ons to pre-configured cabinets and rails, our specialty prep stations are designed for your specific menu items. If we don’t already have something for you, our design engineers have the experience and imagination to create whatever is needed. Whether it’s curved to appeal to front-of-the-house customers, or built precisely for your menu item, contact us to begin the design process.

Every shred of cheese that doesn’t land on the pizza – whether it ends up on the prep table or the floor – turns into costly waste. This is especially true for operations that deal with roller coaster fluctuations of volatile cheese prices. Consistency is also critical to earning customer loyalty. If your pizza has the perfect amount cheese every time, your customers will keep coming back.

The Randell Cheeser Station® has a simple but practical self-contained design that helps give pizza operators 100% cheese utilization. Any shreds that don’t land on the pizza end up back in the 30-pound holding bin – not on the floor or prep table. Download our Educational Guide here!

GRATE

A removable stainless-steel grate holds the pizza during preparation and allows cheese to fall back into the holding bin for 100% utilization.

HOLDING BIN

The refrigerated cold-wall holding bin accommodates 30 pounds of cheese! And an exclusive sealed inside with a cleanout port makes it easy to clean and sanitize the pan opening.

SCALE

A valuable option to the Cheeser Station, the scale quickly trains employees to use the perfect amount of cheese.

Standard features and benefits include:

Available Models:

Find spec sheets for this model on the Downloads tab.

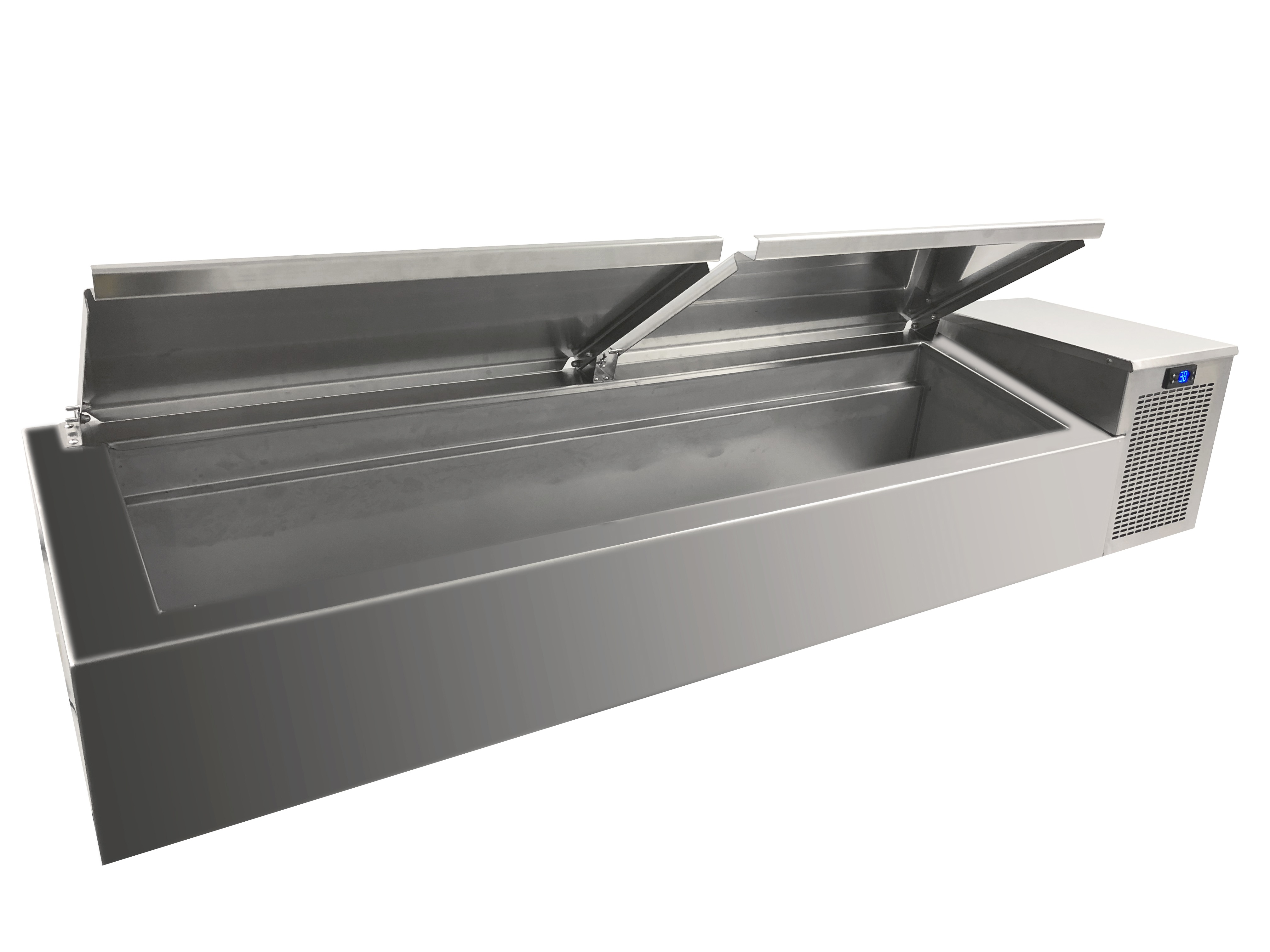

Our countertop rails offer the option of converting existing work surfaces into pan-holding operations in compliance with NSF/ANSI standard 7, 41 ̊F pan product temperatures — all thanks to our innovative rail design that is the result of years of wrapped cold-wall construction experience. Our cold-wall-constructed, self-contained refrigeration system utilizes Zero Ozone Depletion Potential R290 refrigerant with an exterior mounted electronic control provided as standard, which allows for easy temperature adjustment to the rail or to be shut off when not in use or defrosting.

These removable rails hold from 3 to 8 1/3 size pans depending on the model.

Standard features and benefits include:

Available Models:

Find spec sheets for this model on the Downloads tab.

These self-contained ice cream storage and dipping cabinet with mechanically cooled syrup rail are offered in a variety of lengths and capacities to meet your needs. The single opening mechanically cooled raised syrup rail provides easy access and safe holding of syrups and toppings. One piece die-formed 16 gauge stainless steel top is available with slide-top or flip-top cover(s) providing easy access to the ice cream storage compartment.

Standard features and benefits include:

Available Models:

Find spec sheets for these models on the Downloads tab.

Our specialty prep stations are designed for your specific menu items. If we don’t already have something for your item, our design engineers have the experience and imagination to create whatever you need. Whether it’s curved to appeal to front-of-the-house customers, or built precisely for your menu, contact us to begin the design process.

Custom Prep Station Raised Rail “Pizza” Prep Tables:

Custom Prep Station Flat Top “Sandwich/Salad” Prep Tables:

Custom Prep Station Specialty Dipping Cabinets:

Find spec sheets for these models and other custom configurations under Custom Chef Service Counters.

Brochures

Cheeser Station Educational Guide

Randell Prep Stations Brochure

Randell Custom Fabrication Brochure

Calculators

Cheeser Station ROI Calculator

International

DCHFT, DCST & DCFT Models, Dipping Cabinet Series Operator Manual, Canadian French

CR9000-290 Manual, French

Manuals

DPTSK Series Integrated Weigh Scale Kit

MNL2103 RCS-24 Cheeser Station Manual

Custom Prep Table Manual

DCHFT, DCST & DCFT Models, Dipping Cabinet Series Operator Manual

CR9000-290 Countertop Rail Manual

Sales Sheets

Brand Overview Flyer

Spec Sheets

RCS-24 & RCS-24 WS Models, Refrigerated Cheeser Station

DCH Model, High Capacity Dipping Cabinet

DC Model, Dipping Cabinet

WPO Models, Self-Contained Recessed Coldwall Refrigerator

NPO Models, Self-Contained Recessed Coldwall Refrigerator

WPR Models, Self-Contained Raised Coldwall Refrigerator

NPR Models, Self-Contained Raised Coldwall Refrigerator

CR9000-290 Model, Countertop Rail

Warranty Information

Randell Warranty Information